The vision of flawless vehicle documentation

The development of a new vehicle is highly complex and allows several million to trillions of possible combinations in a single test vehicle due to several generation stages of the most diverse components from many suppliers. Error-free documentation of the state of construction is a pre-requisite for the qualitative evaluation of test drives and measurement results in order to avoid false conclusions – and, in the worst case, any recall actions that may arise as a result.

Documentation systems that are based on paper and barcode scanning have been found to have an error rate of approximately 30% incorrect documentation data across all manufacturers. This means that many multiple readings, resulting in the complete removal and reinstallation of components, are necessary. The expense is immense.

The vision, on the other hand, is simple: to use RFID to automatically and precisely identify all components in their installed state within the shortest possible time. This is now reality.

Data Elektronik with Porsche and MHP as pioneers

The world’s first transparent prototype was implemented by Porsche as the fitter of the pilot supplier in collaboration with the consulting firm MHP and Data Elektronik as the technology supplier. In 2012, the effective standard was published simultaneously by the VDA as Recommendation VDA 5509. As a general software provider for suppliers to create component labelling with RFID, the data software was subsequently christened RCOM VDA 5509.

Where initially a dozen automotive sub-contractors produced RFID tags for Porsche, Data Elektronik now supplies more than 500 suppliers for Porsche, VW, Audi and BMW with software, RFID printers, mobile RFID handhelds and, of course, RFID labels and hard tags. Data Elektronik has thus established itself as the market leader and also supplies sub-contractors for VW and BMW in series production.

A complete solution for suppliers

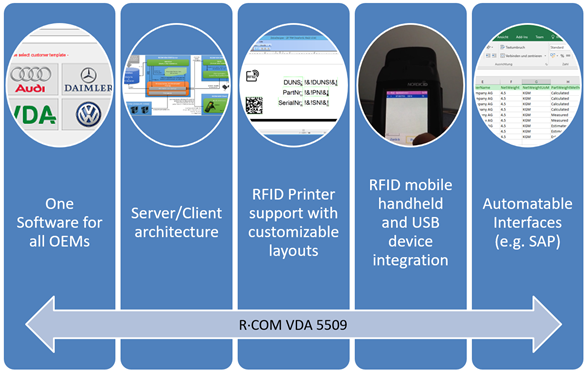

With the RCOM VDA 5509 software, Data Elektronik has created a de facto standard for automotive suppliers with a range of functions that is unmatched on the market.

- Server/client architecture for any distribution required on virtual servers or individual workstations

- Integrated control of RFID printers, mobile RFID handhelds and RFID readers connected via USB

- All OEMs that use RFID-tagged components and their codes are integrated

- Printer layouts can be freely adapted in order to attach additional internal data to the RFID label

- CSV import of components possible

- Automated file interface for ERP integration available

- Data export in XML/CSV formats as specified by the OEMs available

- Scalable from a single-user application for pre-series to a large number of users and series production