One solution for all use cases

With our history as the world’s first system supplier of transparent prototypes and the expansion into series production, RCOM VDA 5509 software is the market leader for automotive suppliers in the area of RFID component tagging.

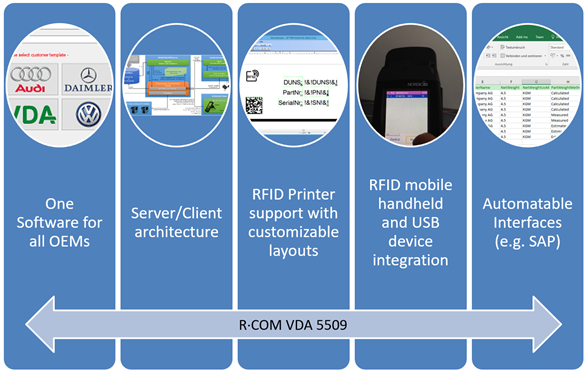

Right from the start, it was important for us to create a solution for all automotive suppliers, regardless of which vehicle manufacturer was interested. It is our philosophy that you should not require a new piece of software for every customer – you should be able to handle all use cases from pre-series and series production through to component design and automated end-of-line inspections at the belt with a single solution. Focus your energy on what you do best while we take care of coding schemes, barcode content and printer and reader control systems for you.

Support for all OEMs

Recommendation 5509 of the VDA was published with the introduction of transparent prototypes and set the basis for RFID coding in the automotive industry. It is also where the software got its name. While not all manufacturers currently comply with the VDA specifications, or indeed will comply with them in future, we make the promise to integrate all codes for RFID components into the software. The software is therefore regularly expanded with updates. This also saves you the time and effort of having to take care of every coding requirement yourself, whether PLC programming, SAP printer control systems or other interfaces. These problems can be completely taken care of by the RCOM VDA 5509 software.

Standards supported: VDA 5509, VW01067, VW01064, BMW GS-91010

System architecture

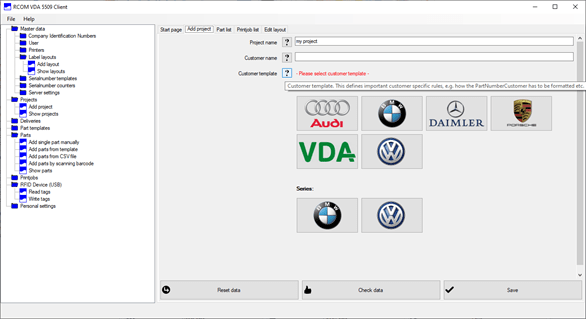

Despite modest beginnings with just a few thousand RFID components per supplier in the prototype phase, the software was designed directly for a scalable server/client architecture. Data can be stored in a simple file format or on an MS SQL database. The system offers user and rights management, automatic updates, print queues, a parser for your own serial number generation and layout design. It also has automatable interfaces, component generation in accordance with OEM regulations and reader and printer support. The system is also multilingual and is delivered with both English and German texts which you can independently adapt and expand. This is relevant for corporations with multiple locations, particularly in light of the recent increase in series production with multi-user environments.

In short: with RCOM VDA 5509, you will receive the most powerful framework available for this application in the sector.

RFID label printing

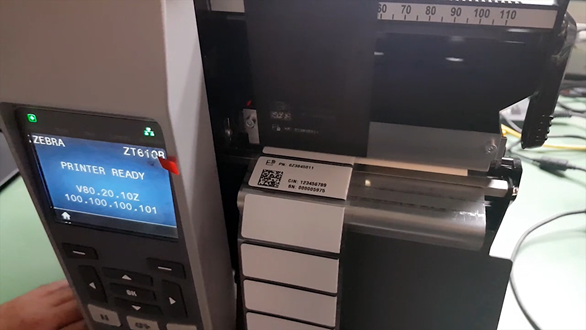

Assuming you do not want to manually describe each RFID chip individually, an RFID printer will be the most important tool in most suppliers’ arsenal. The device codes and prints the RFID label in a single step while checking the RFID coding at the same time. RFID labels that can be applied to metallic surfaces (known as on-metal labels) are normally too thick for RFID printers. Therefore, in consultation with Zebra, we have modified the R110Xi4 and ZT610R models such that they are capable of printing all on-metal labels known to us. This is unique in the world and can only be ordered from Data Elektronik.

If your piece numbers are small and demand is only sporadic and plannable, we can also supply you with printed and coded RFID labels. This can be a cost-effective solution for you, particularly in the prototype phase and in pre-series production where piece numbers are low.

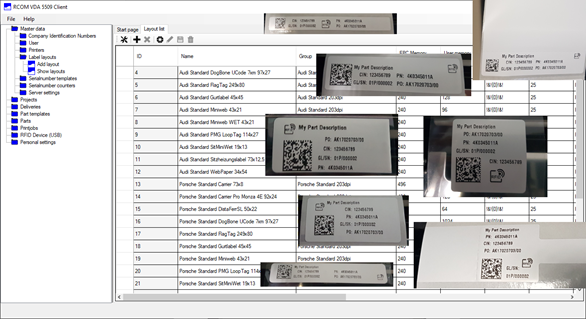

Pre-defined layouts

We want to lighten your workload as much as possible, so we have created layouts for each OEM in all commonly used standard formats which you can use right from the get-go. We have also pre-programmed the RFID writing parameters directly into the software for standard printers in order to save you the calibration. In total, there are now over 100 label layouts stored for your convenient use.

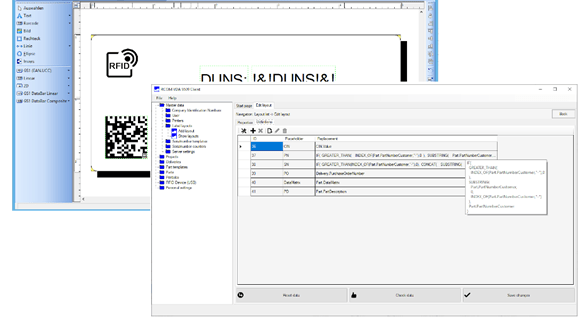

Custom layout design

If you plan to use RFID labels for both your customers and internally within your company, it makes sense to include additional information on the label. This might simply mean including your own logo for corporate identity. RCOM VDA 5509 allows you to design label layouts according to your needs, avoiding the need to purchase additional layouts. You can use any ZPL-capable label designer software (we recommend the free ZebraDesigner Essentials 3 in our manual) and integrate it into the software. When it comes to field allocations, all database fields are available for project, delivery and parts data, including a formula editor that functions like the editor in Excel. And should you want to avoid the extra work, you can even have Data Elektronik perform the layout creation.

Support for mobile RFID handhelds

After the components have been tagged, there are often still many process steps where the reading of tags may be relevant. For example in quality control, component localisation (“dowsing rods”) or loading inspections. We have developed a mobile app for this purpose that can be used fully offline with no server connection to check tags – individually or as a group reading. With a wireless connection to a RCOM VDA 5509 server, you can also read component data for a tag from the database, transmit bulk read results directly to the server and write or overwrite individual tags.

Support for RFID USB readers

For simple requirements with a low number of pieces, a mini RFID reader connected to the PC by a USB cable will be sufficient. This can be used to read and write tags. A connection to a Windows PC running an RCOM VDA 5509 client is required.

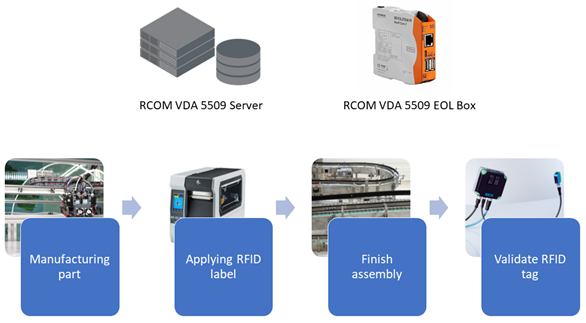

Integrated end-of-line inspection

In series production, an end-of-line inspection is important to check the labelling and RFID tag. In most cases, the DMCs (DataMatrix Codes) created are checked for legibility with stationary camera systems prior to delivery, as the OEM expects guaranteed legibility and wishes to avoid quality defects upon delivery as far as possible. The same now applies to BMW suppliers, as the use of RFID is being promoted in series production at BMW in particular. With this in mind, we have developed a special standardised package which can carry out the following tasks for you:

- Automatic readouts with RFID readers/antennae on the belt, triggered by light barriers

- Checking the RFID tags for legibility and correctness of the data

- Validation can be compared with the print jobs created, providing that printing was also carried out by RCOM VDA 5509 – “missing” numbers can be detected via sequencing logic and reported

- Software can be controlled via the RCOM VDA 5509 server or, in a decentralised case for use at the machine, via an EOL box supplied by Data Elektronik (a Raspberry Pi)

- Previous print orders from a machine for BMW can be used directly for printing, coding and counter-checking via an EOL box with no additional programming in the PLC control system

Premium reseller and service partner for RFID equipment

All of the equipment and consumable materials that are required as a supplier can be provided by Data Elektronik. As we deliver continuously to hundreds of suppliers, we have established a large warehouse of the necessary RFID equipment and consumable materials and can therefore deliver to you as quickly as possible. This includes:

- RFID printers and/or applicators

- RFID labels with more than 20 different label types in commonly used standard formats

- RFID hard tags including high temperature requirements

- RFID handhelds for group readings and manual reading/writing of tags

- RFID reading devices for automated end-of-line inspections

- RFID USB readers for inspection processes

- Appropriate ink ribbons for thermal transfer printing

- Barcode scanners for DataMatrix inspection