Tracking

Recording is the central component in every traceability solution. The materials to be tracked must be recorded in the logistics stations that they are due to pass through in order to be able to see the flow of materials in real time and ensure seamless documentation. This continues to be performed manually in many cases, be it manual bookings at a terminal, records and checklists on paper or the scanning of barcodes. These records can be fully automated using RFID – provided the pre-requisites are present – reducing the amount of time required in logistics processing and minimising the potential for errors.

Tracing

Decisions require a great deal of information. Examples include the throughput times for materials in manufacturing, periods of retention for containers in warehouses or with suppliers and analyses of stations that are passed through. With regard to production and quality management, the seamless tracking of the individual component parts of end products is of interest in order to be able to quickly limit and localise affected end products in the event of a complaint. It makes a considerable difference here whether, in the case of a recall, tens of thousands – or even a million – products from a batch have to be recalled across all customers, or whether the supplier’s defective components can be accurately and individually traced back to the affected customers and locations.

The appropriate technology for your use case

In order for your solution to function, the technology must meet your requirements. With RFID, there are a large number of important factors that may make the difference between a success and a lost investment. It is essential that you can rely on a partner with comprehensive expertise in the field of RFID. As a solutions provider, we offer the following services, among others:

- Analysis of objects being tracked

- Analysis of processes for the traceability solution with recommendations for best practices

- Feasibility studies and pilot tests

- Selecting appropriate technologies (for example LF/HF/UHF)

- Delivery of RFID labels or hard tags

- Delivery and commissioning of the appropriate hardware to record objects

The appropriate software for all use cases

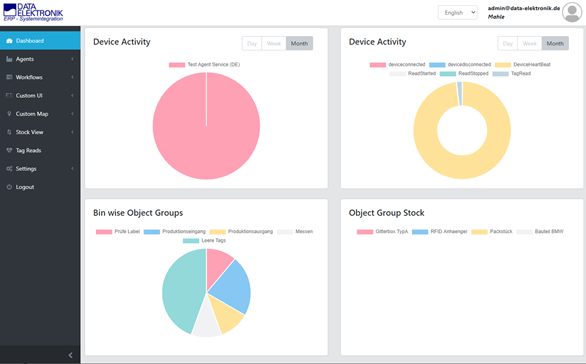

We recommend the use of our RFID middleware / IoT platform to ensure you get the most out of your RFID infrastructure. You will thus have all results available in real time and will be able to monitor the RFID hardware permanently and conveniently control the event processing for posting the recorded data in a centralised manner. The following sub-functions are relevant for traceability, among others:

- Device management of RFID readers and antennae as well as printers and mobile devices from various manufacturers

- Classification of objects into user-defined object groups with general properties

- Automated identification of parts and groups for dynamic further processing

- Real Time Location System (RTLS) for monitoring the current locations of tagged objects, contents and orders

- Interfaces for backend systems, such as SAP for example