The benefits of asset inventories with RFID

RFID is generally most useful when an object is equipped with an RFID tag for the duration of its service life and can thus always be automatically recorded and easily located. An RFID solution is always cost effective if there is hardly any hardware required. It is always easiest and quickest to use an RFID solution when no ERP integration such as SAP interfaces are absolutely necessary. All of these apply in the case of our solution for asset management via RFID.

The ROI is already there from the first completed inventory due to the savings in manual search efforts. In addition, assets can be monitored much more easily instead of inspections only being carried out every 3 or 5 years. Missing assets are not only a problem for accounting, but can also quickly slow down processes if, for example, auxiliary or raw materials cannot be located or if clarifications require a large amount of effort and resources.

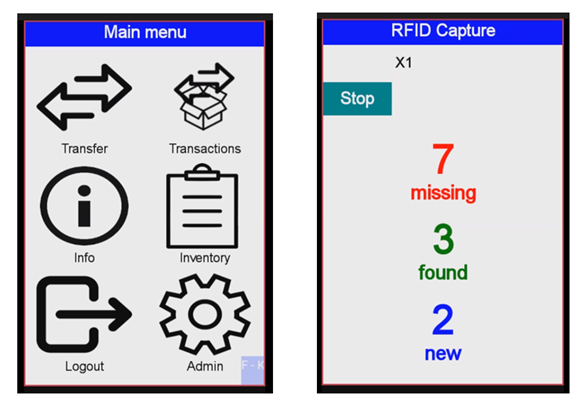

Standardised app with options for adaptation

With our Digital Inventory app, your employees are guided through the inventory process with an intuitive, easy to operate and multi-language app. Pre-loaded inventory lists can be loaded onto the device, or the recording can be started directly. The device can also be used to simultaneously capture barcodes if assets without RFID tags are also present in the asset inventory. Before each change of location, the employee scans a room barcode or selects a location from a list. All RFID tags recorded thereafter are thus automatically assigned to this location. Selection criteria enable finer granulation if required. By logging on to the device and using the appropriate user authorisations, reference information can also be called up, or tags can be overwritten directly with the device.

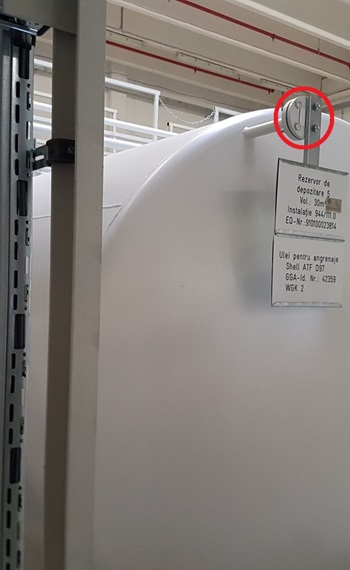

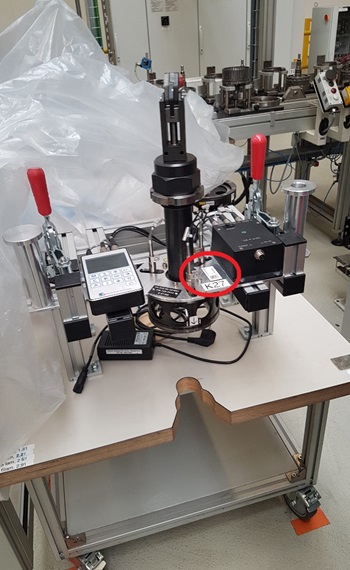

The complete range of accessories

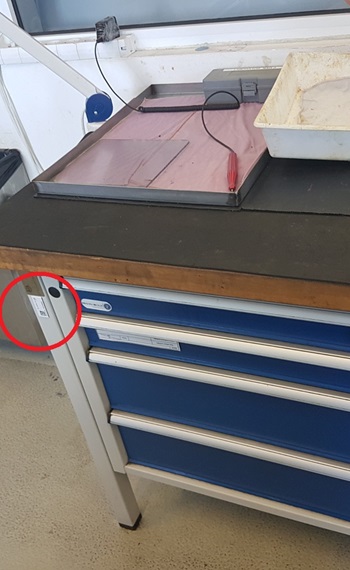

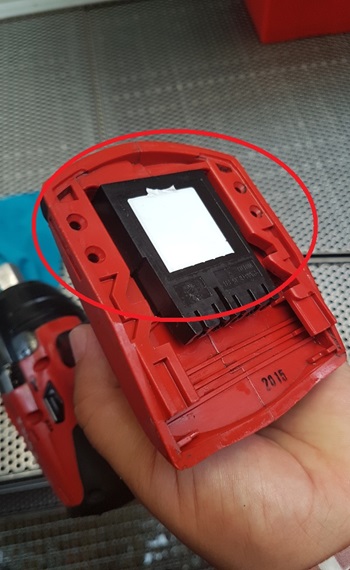

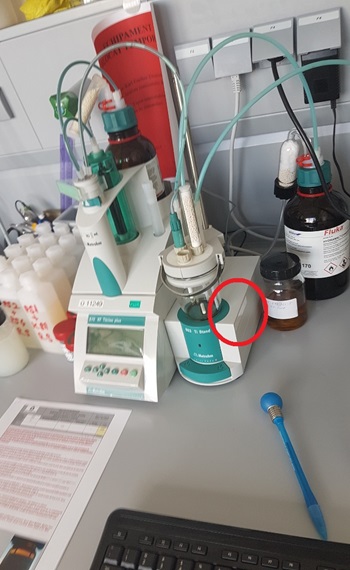

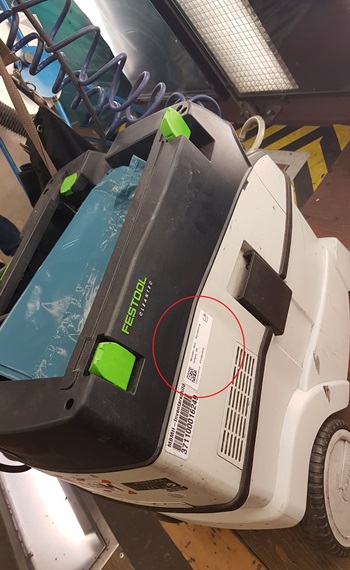

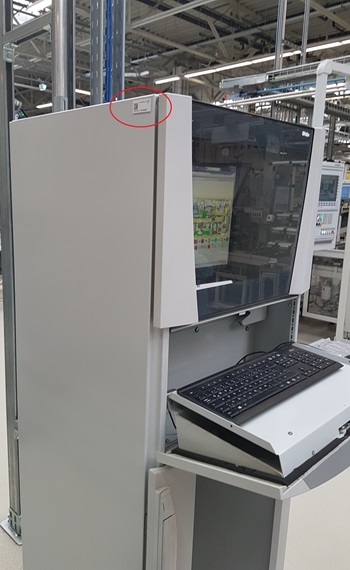

To enable your equipment to be found from as great a distance as possible with passive UHF tags, the performance must be as high as possible. This is derived primarily from the size of the antennae, which means that compromises often have to be found here. Deciding whether a tag should be made with a metallic, conductive surface or a non-metallic surface is also important for tag selection. Thanks to our many years of experience, we are able to offer you a set of established standards for a high number of variants, while minimising the variety used as much as possible.

We will of course be happy to offer you RFID printers together with the software to equip your assets with RFID labels as well as the mobile handhelds with RFID antennae. As a complete service provider, we can also offer you subsequent servicing and repairs for all of the hardware that you purchase. Rental devices and pre-printed and coded RFID tags can also be obtained.

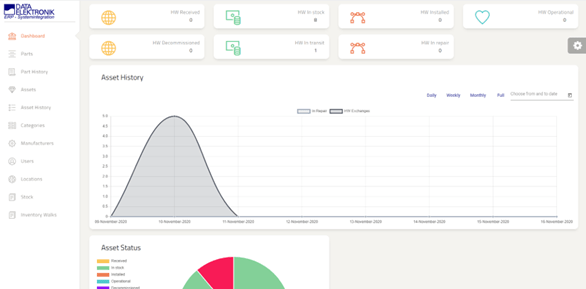

Interface or stand-alone solution

Excel imports and exports are popular as the simplest and quickest-to-implement variant. Commonly used ERP systems such as SAP are able to output inventory lists for assets in Excel/CSV and import recorded data via Excel/CSV. No additional integration is needed here. Various interfaces are available for direct integration with query and information options or direct posting of entry lists in e.g. SAP FiBu or PM.

For a more complex stand-alone solution, we have developed a database with a streamlined user interface specifically for asset management that you can use out of the box. The solution can also be used for interfaces and Excel exports and imports.