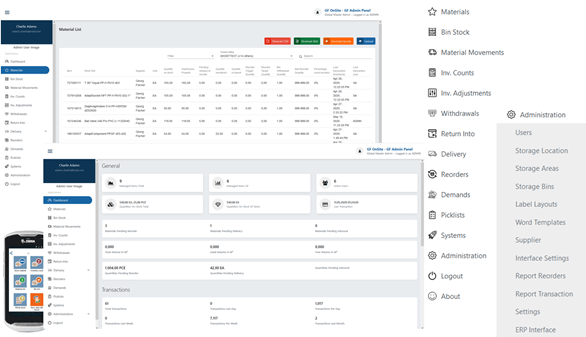

Streamlined, efficient and elegant

We have drawn on our decades of experience in warehouse management to develop a warehouse management system which is as streamlined, intuitive and transparent as possible – yet still powerful enough for most requirements. RCOM WMS (warehouse management system) is quick to set up, easy to learn and powerful thanks to its additional modules and configuration options.

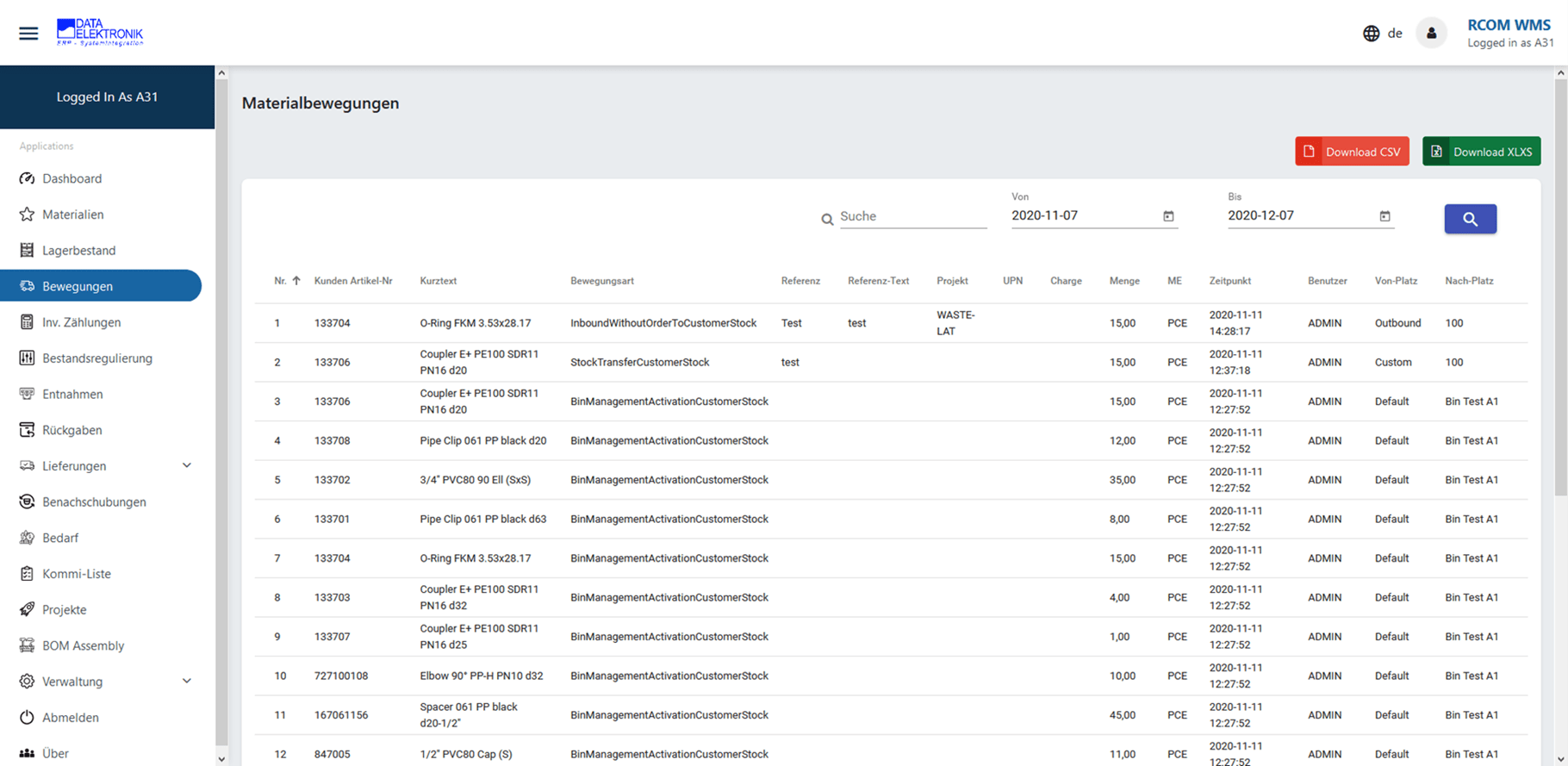

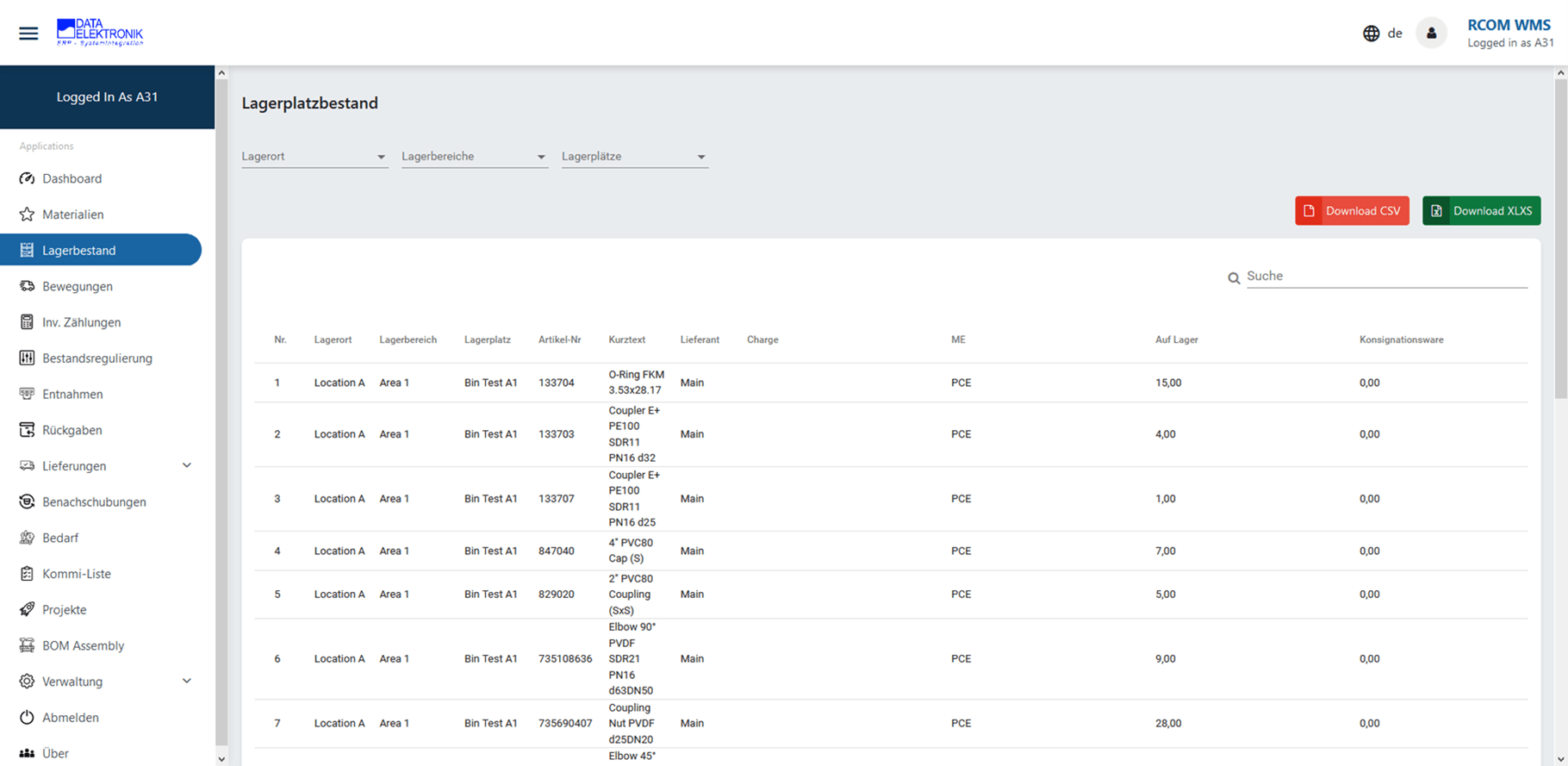

The interfaces have been designed like modern websites and are responsive and extremely easy to operate. There is no need to install additional client software on the computers and the interfaces are independent of the operating system used (Windows / MAC OS / Linux). RCOM WMS has been internationalised and is available in multiple languages. The texts displayed can also be changed independently via an administration menu and adapted to the respective company jargon.

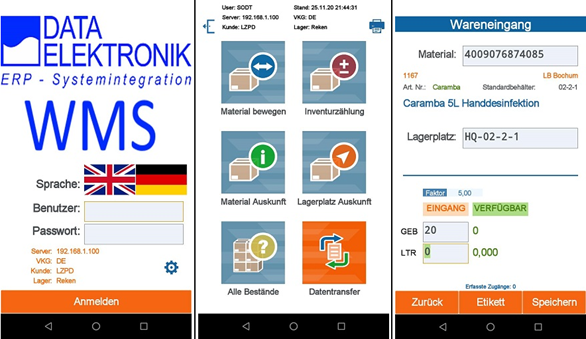

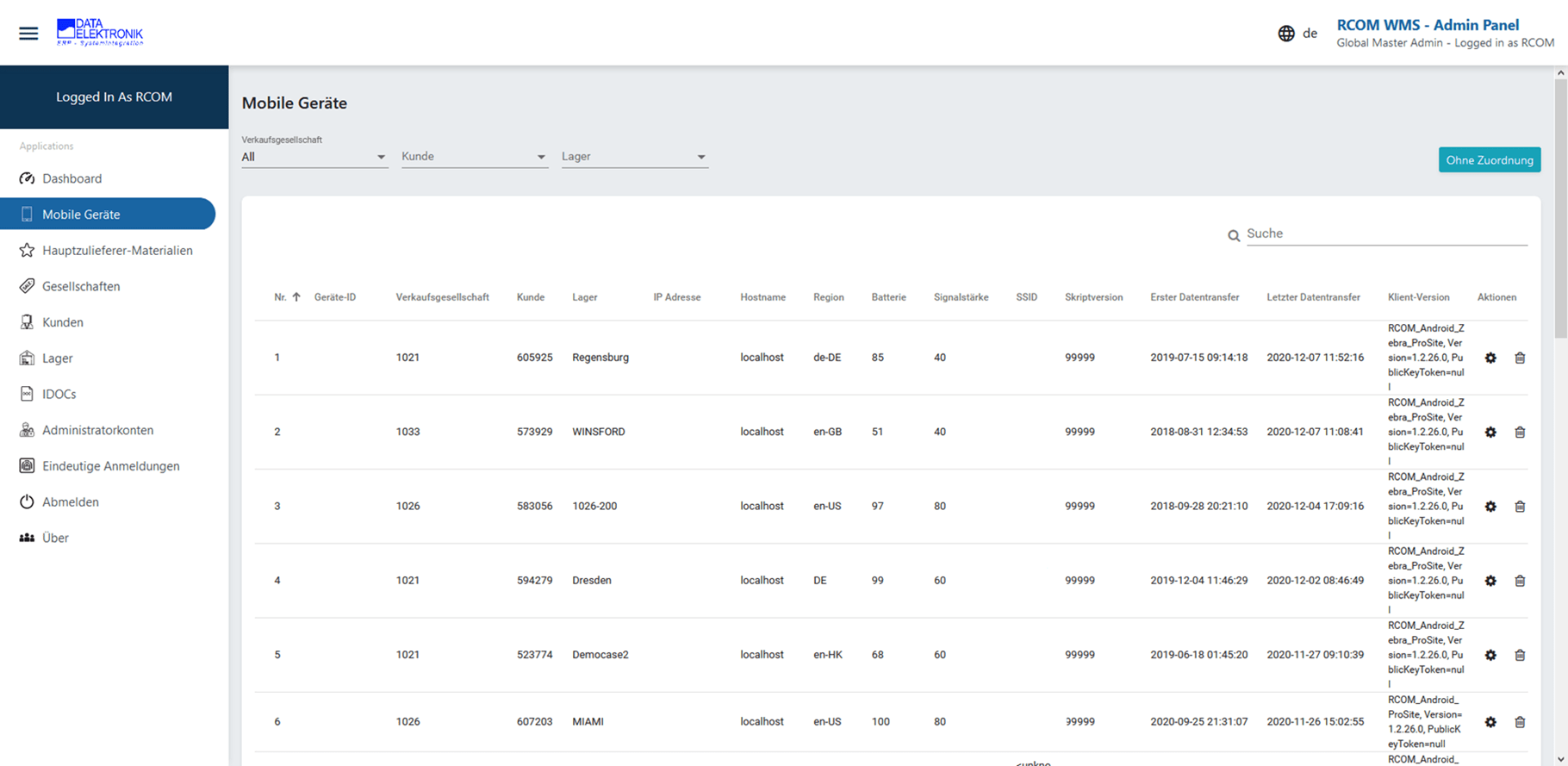

Mobile app for scanners and smartphones

As experts in scanning & mobility, we have of course also developed a corresponding app for scanners and smartphones. The app can run completely offline, i.e. it can buffer data until it is transferred. The following functions are available via the app:

- Incoming goods for purchase order

- Incoming goods without order

- Redistribution

- Inventory count

- Outgoing goods on picking order

- Outgoing goods without order

- Creation of delivery note and digital signature

- Material information

- Inventory information

Modular structure

So that you only pay for functions that you actually need, RCOM WMS has a modular structure and will always be able to be expanded in the future. The following modules are available alongside the basic module:

- Asset management

- Document management

- Continuous inventory

- Container management

- Production order management

- RFID expansion

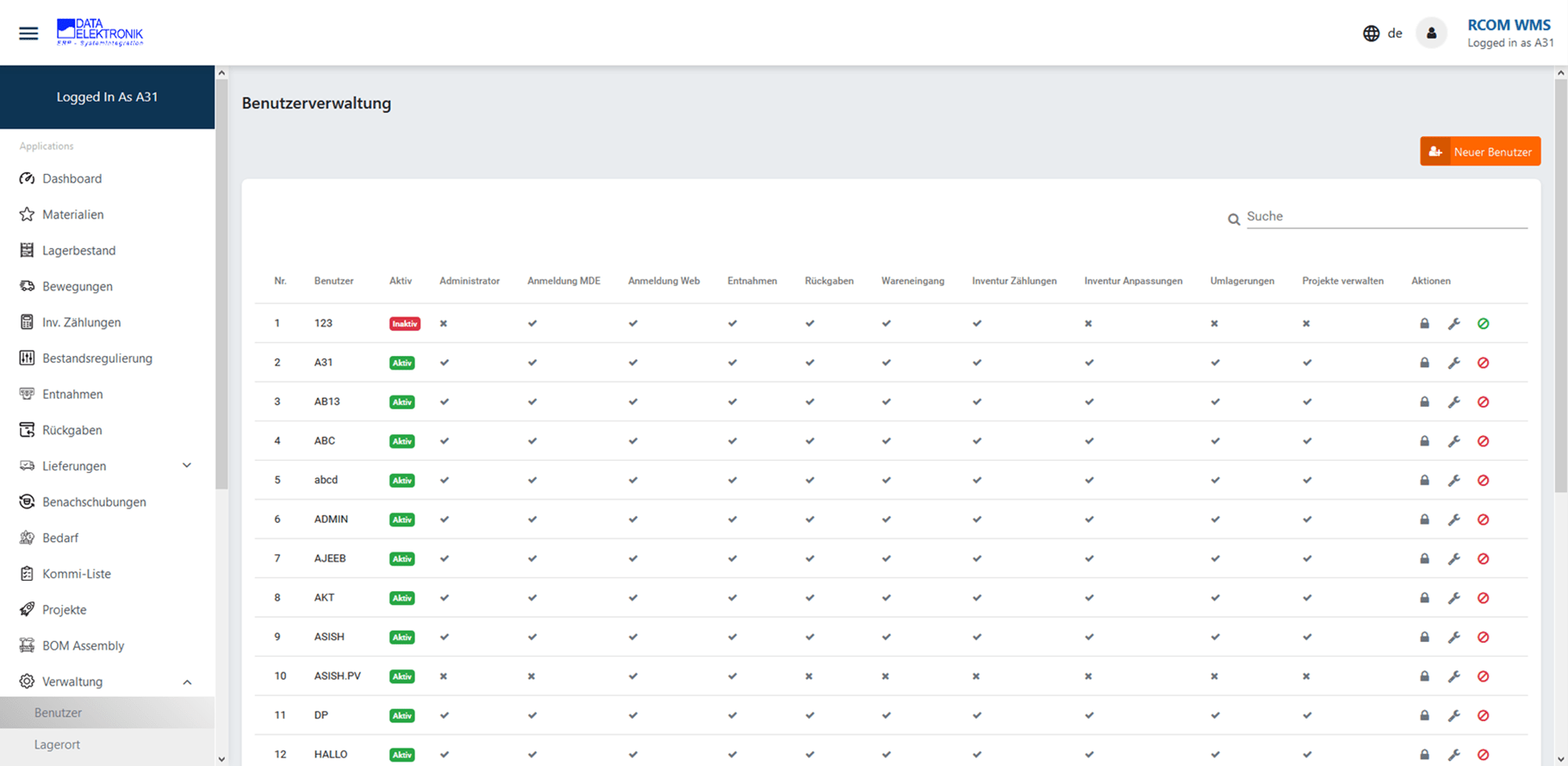

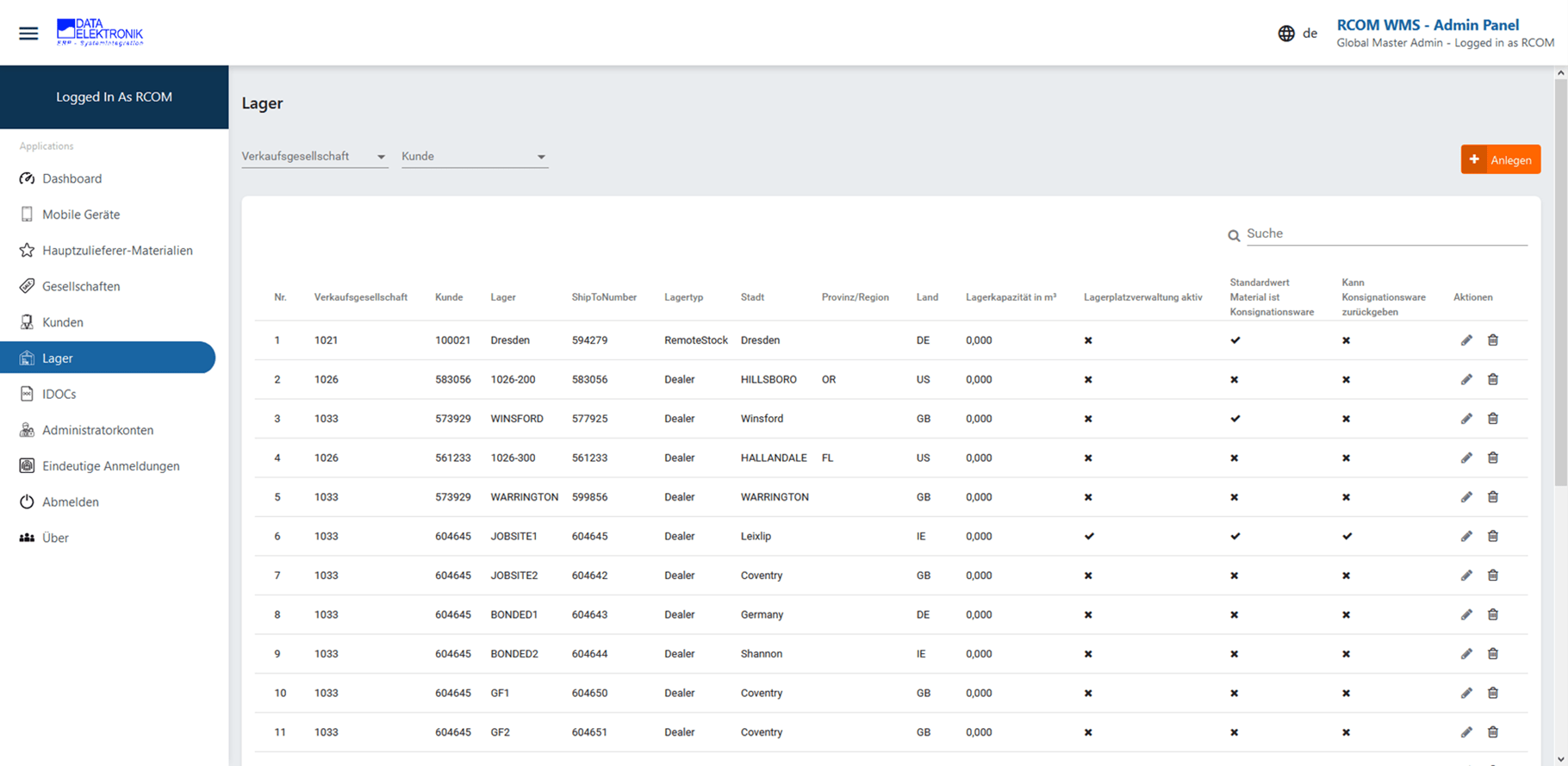

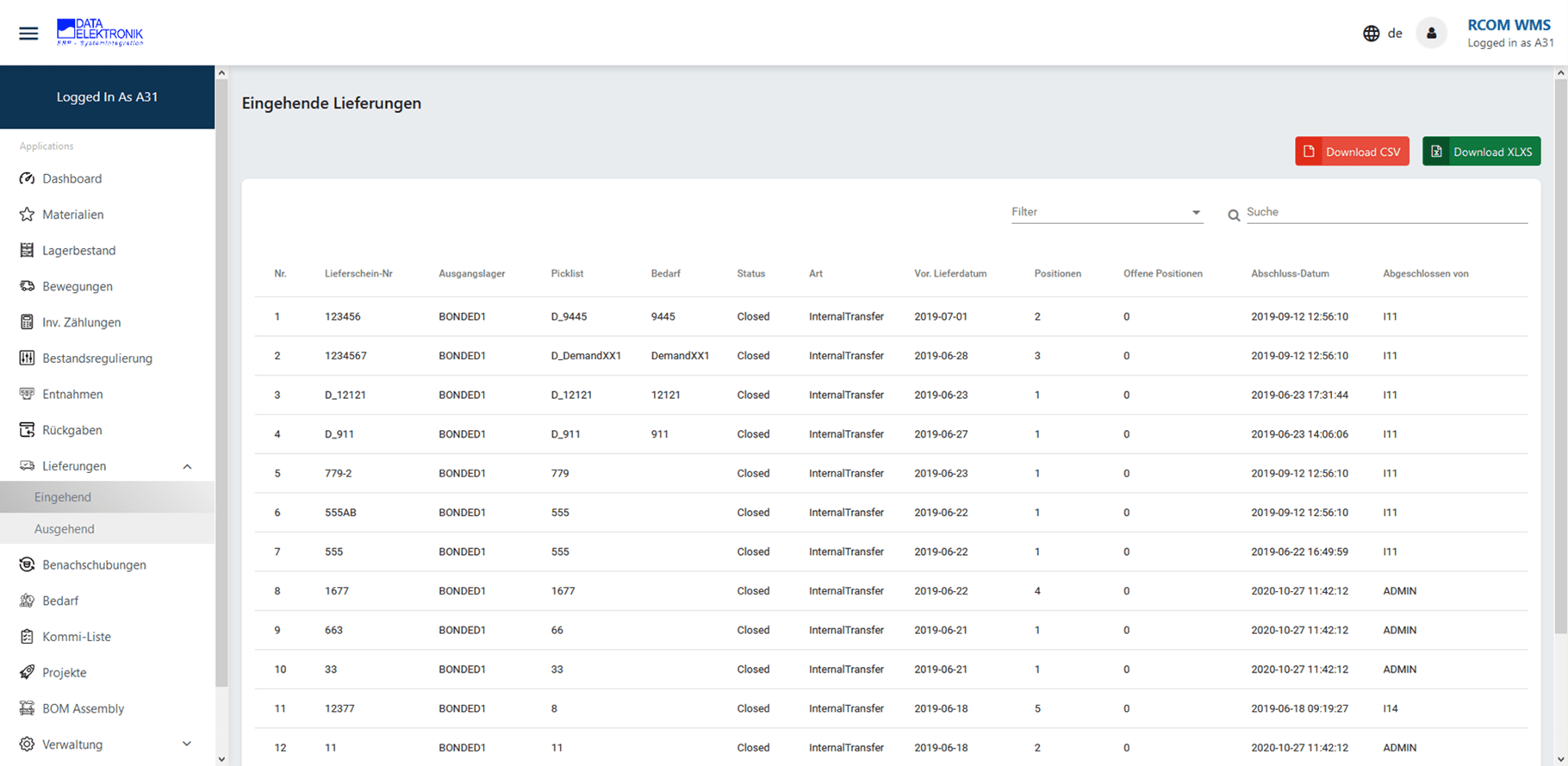

Cloud or on-site

You can use the software on a Software as a Service basis (SaaS, simply known as the Cloud) or you can install the server in your company network yourself. RCOM WMS has a multi-layered multiple-client capability which is hierarchically divided into clients, customers and customer warehouses. Individual users can thus be easily allocated to a customer warehouse and only have access to its data. Or you can create admins for the customer which have access to all customer warehouses. There are also analogue admins for the complete client and a Super Admin access. Overviews can be output cumulatively or individually depending on the access level.

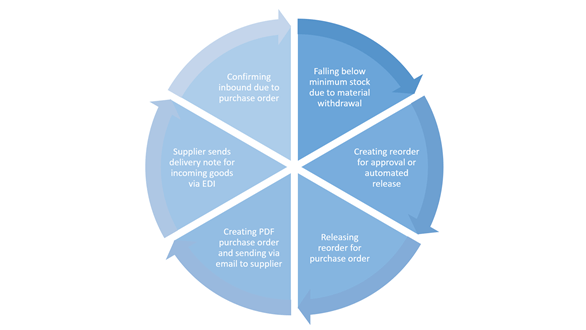

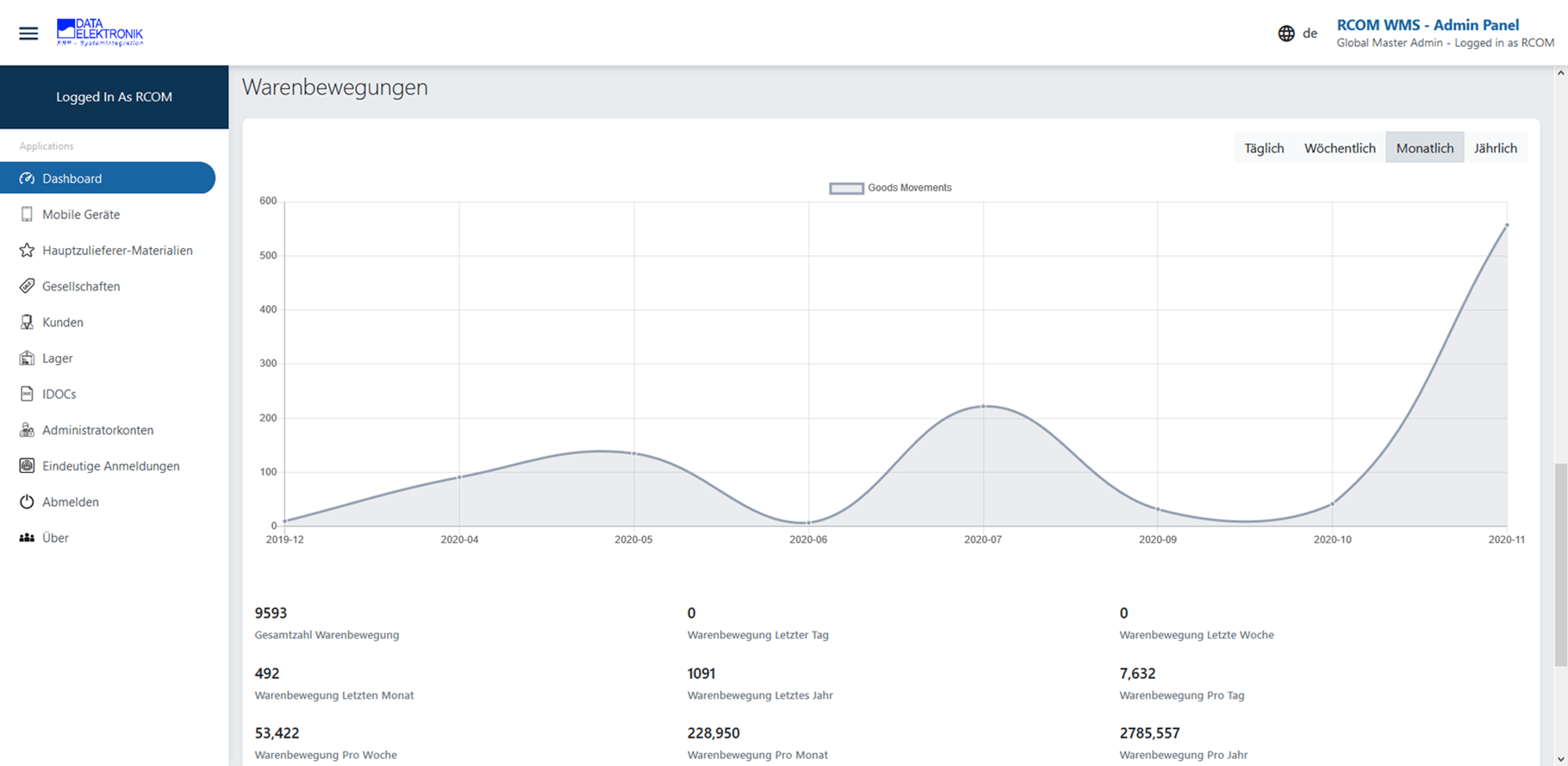

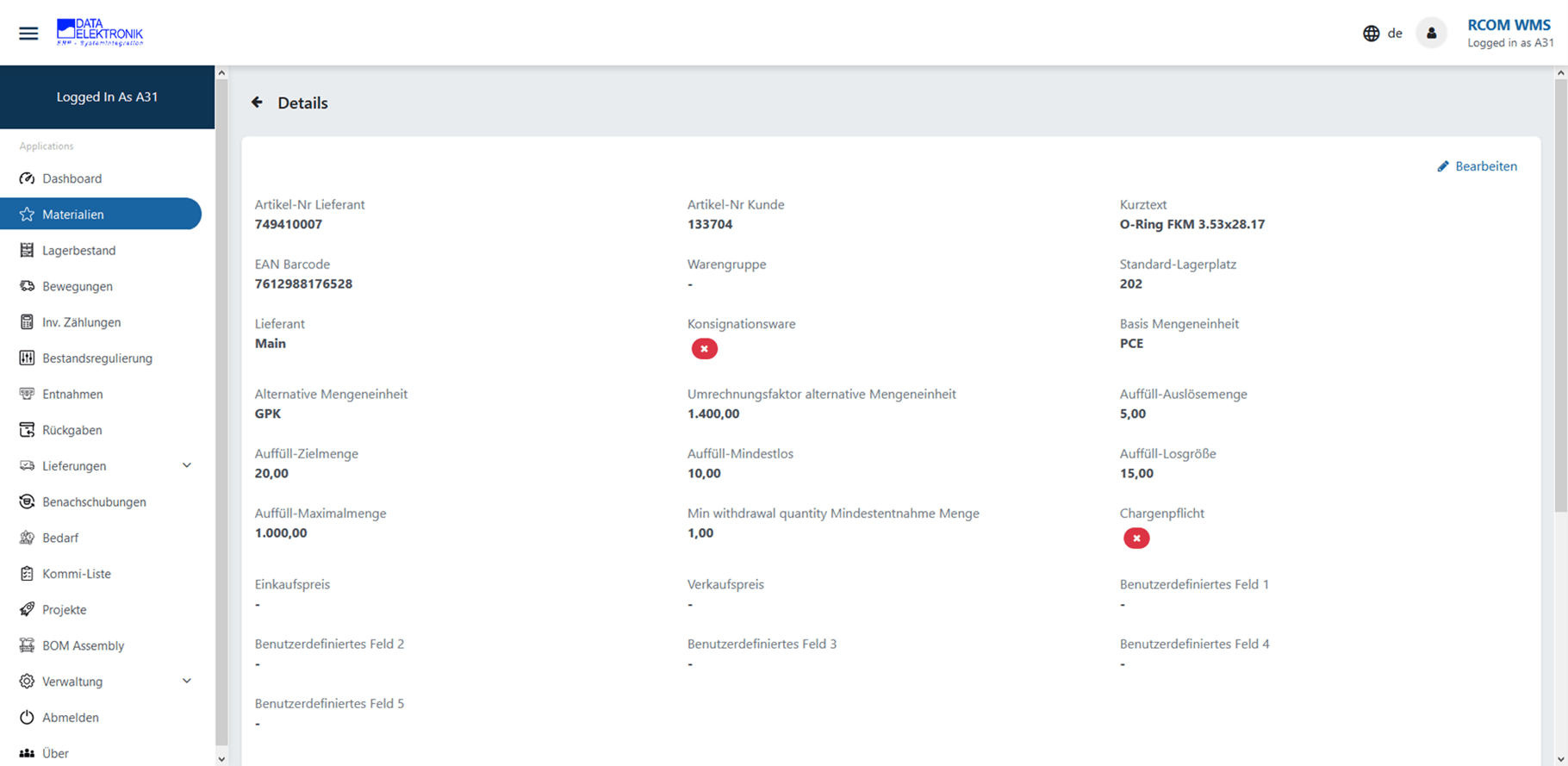

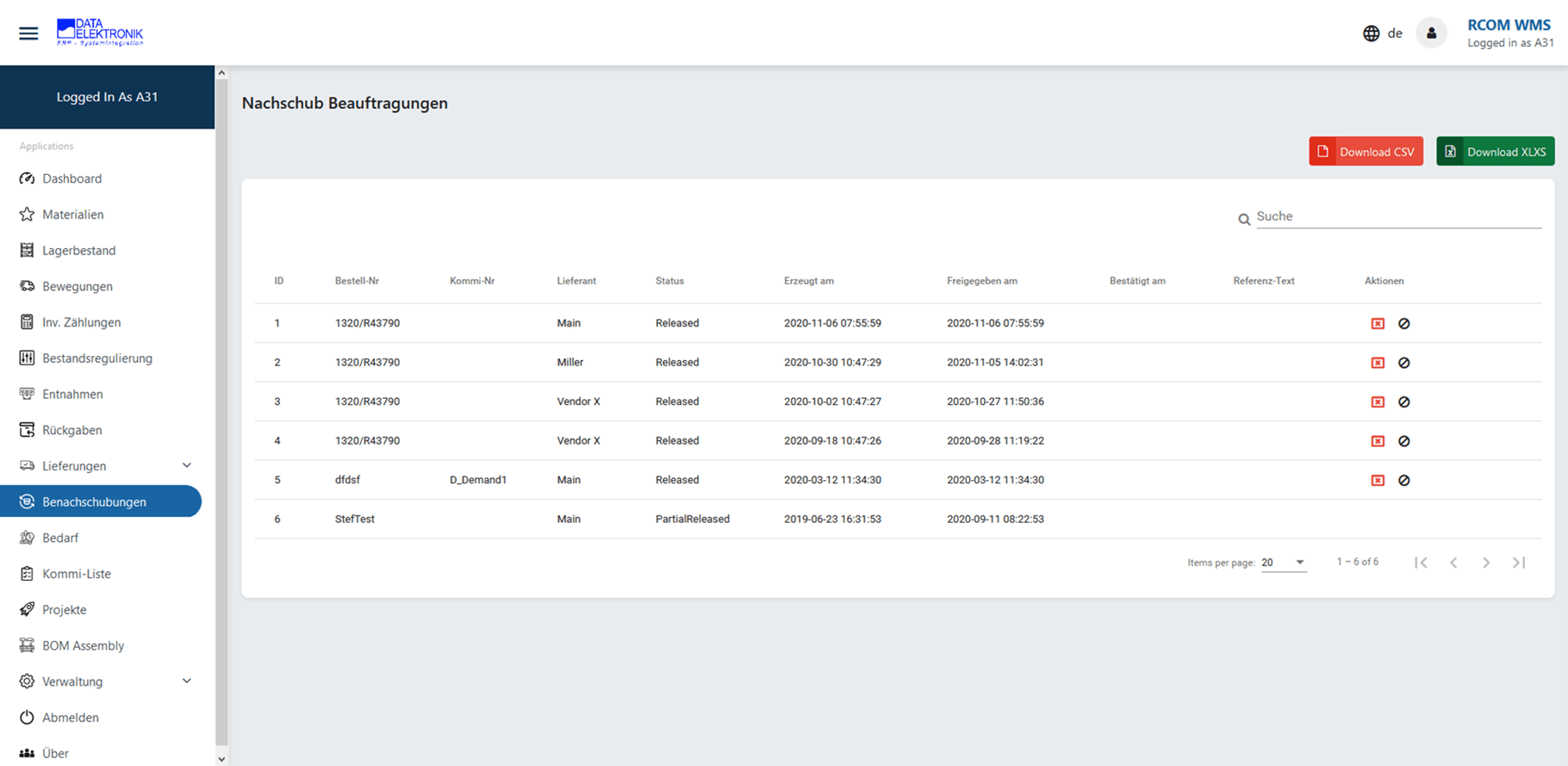

Reporting volumes and replenishments

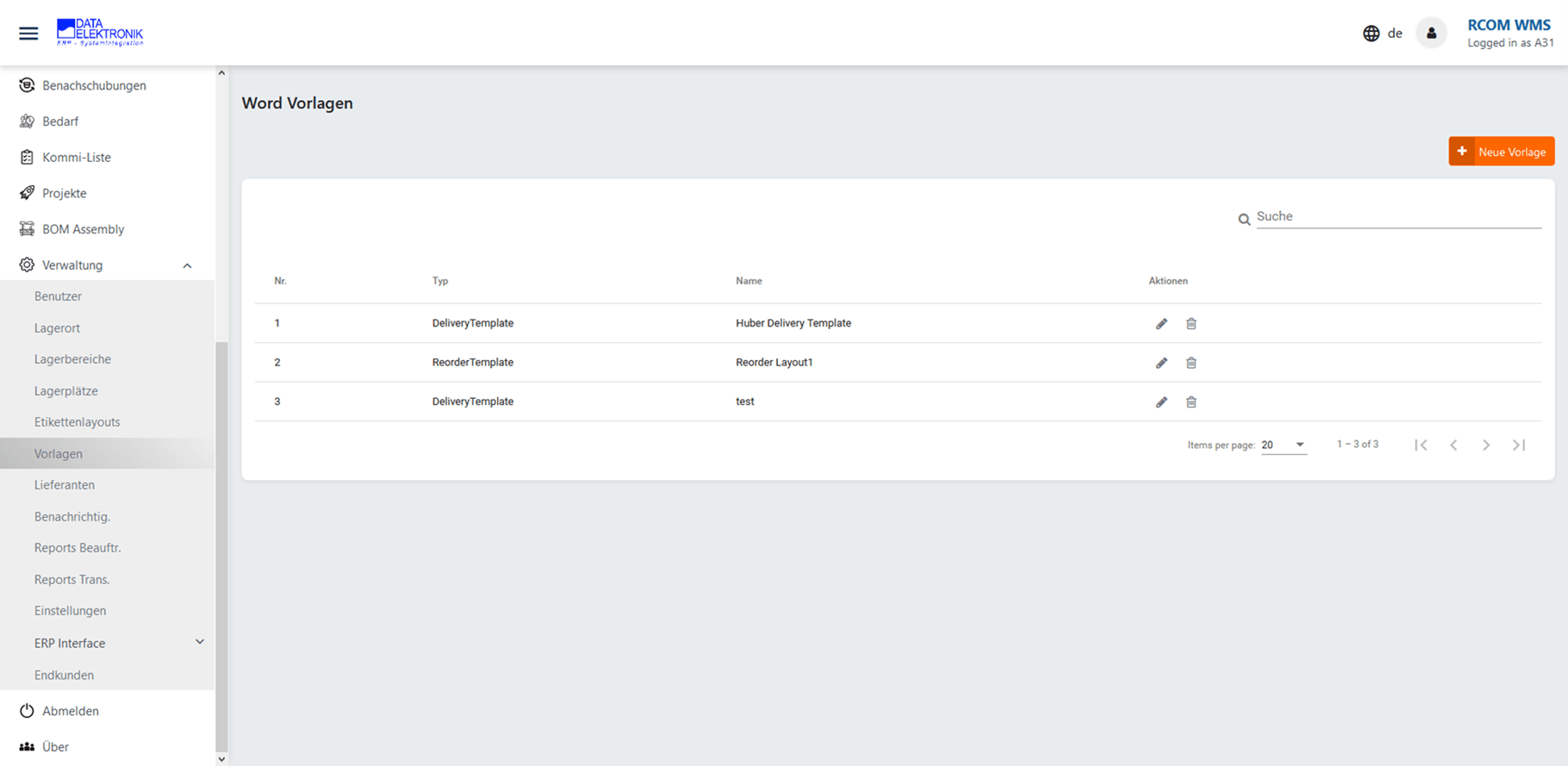

The system can differentiate between supplier-owned and warehouse-owned stocks and can therefore create withdrawal messages – effectively the goods being purchased – to the supplier when goods are issued. There is also the option to set replenishment control parameters for minimum quantities, target quantities, batch sizes and maximum order quantities for each material. In this way, you avoid production bottlenecks or delivery problems by automating ordering processes. Replenishment can be completely automated or handled via manual release processes. You can also upload simple Word templates for output orders, which are automatically filled with data by RCOM WMS. And if the minimum quantities for each material and warehouse area have to be structured differently right down to the individual warehouse space, then this can also be activated.

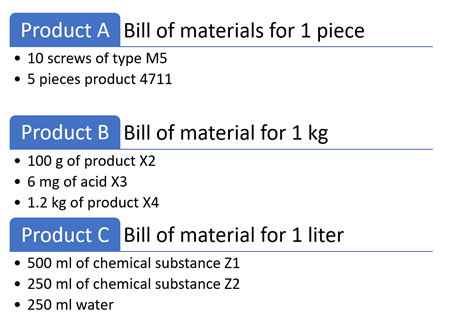

Parts lists and manufacturing

Parts lists can be used for both order picking and production. This allows recurring sets to be summarised as a bill of materials at goods issue, which the app then automatically breaks down by component and withdrawal storage location for the employee on the handheld. The individual components can then be recorded in production acknowledgements in the course of production.

Versatile interfaces

The RCOM WMS is capable of running both as a sub-system to a leading ERP and as a stand-alone system. When it comes to exchanging data, there is a flexible ERP interface system allowing any data content to be transmitted in any desired format desired via any transmission method. Put another way: which data should be transmitted in which format, how and to where? A small selection as an illustration:

- Excel format

- CSV format

- XML format

- JSON format

- SAP IDoc format

- FTP Upload transmission method

- WebService transmission method

- Sending by email transmission method

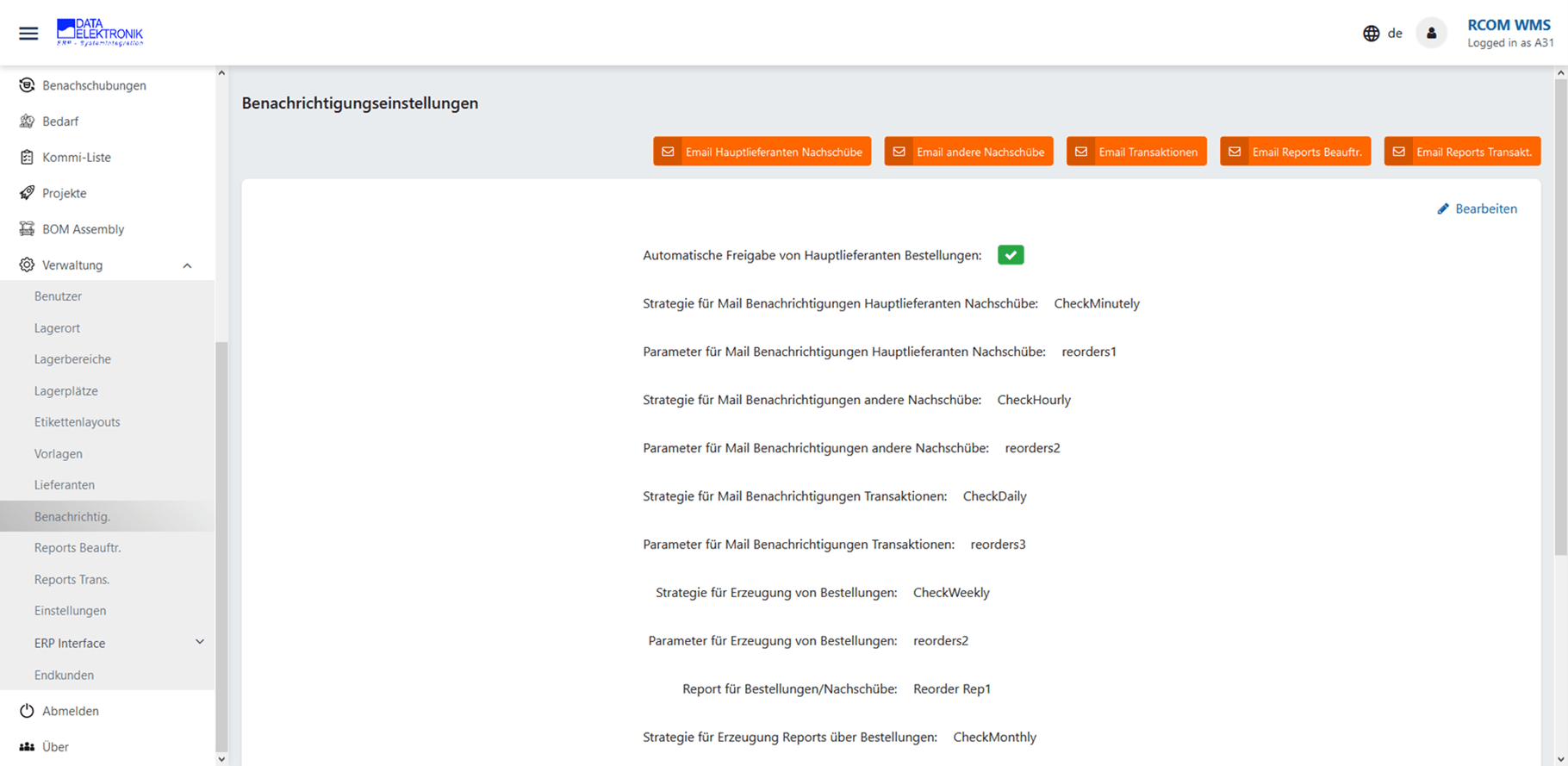

- Time-based trigger (e.g. every x hours, or every Wednesday at 8pm, etc.)

- Event-based trigger (e.g. if incoming goods are posted, or replenishment is created, etc.)