Permanent labelling or single use

An important initial question for your container management scenario is whether the containers affected are your property or at least return through defined circular flows (returnable assets), or whether the attached RFID tag is used only for a logistical process with outgoing goods and is then removed (single use).

These two scenarios have different approaches for the tagging and logistical processes. For example, the coding of the RFID chip and the attachment of RFID labels must be carried out continually in a single-use scenario. A well-known example of this is the Global Transport Label. The application can be carried out manually here, or automated using applicators. For containers that are permanently marked, the contents of the container must be recorded every time the container is filled or emptied. In hybrid scenarios, traditional barcodes for the transfer of container contents are also sometimes used, while the movements of the container are recorded automatically using RFID.

Recording scenarios

Depending on the type of container, manner of stacking, method of transportation and surroundings, several factors must be observed for RFID recording to ensure a high level of readability. Relying on our many years of experience, we can provide you with the best advice for appropriate RFID tags, gates and transport regulations.

System integration and data processing

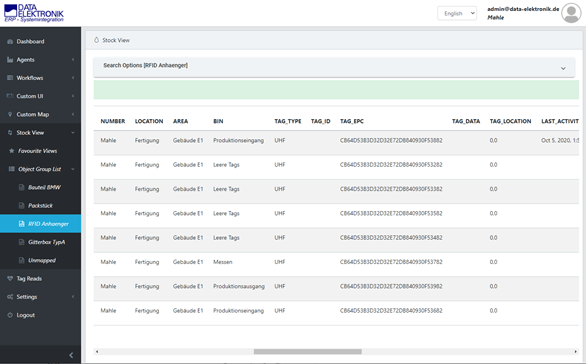

We recommend the use of our RFID middleware / IoT platform for the controlling of RFID reading devices and the processing of read events. You will thus have all results available in real time and will be able to monitor the RFID hardware permanently and conveniently control the event processing for posting the recorded data in a centralised manner. The following sub-functions are relevant for container management, among others:

- Device management of RFID readers and antennae as well as printers and mobile devices from various manufacturers

- Differentiation of different types of containers with defined properties

- Automated identification of container types and serial numbers, and allocation of processing regulations

- Real Time Location System (RTLS) for monitoring the current locations of all containers

- Interfaces for backend systems, such as SAP for example